Classification introduction of Fireproof Expansion Sealing Strips

Apr 19,2023

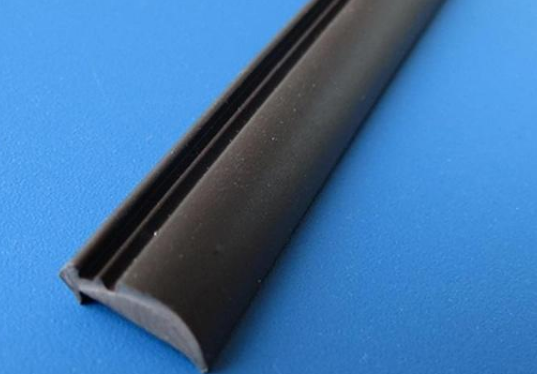

Fireproof expansion sealing strips have excellent fire resistance and expansion performance, as well as good flexibility. They also have superior sealing and vibration isolation performance. In addition, due to the adoption of extrusion technology, the convenience for users is enhanced, and various shapes and arbitrary lengths of flexible refractory expansion sealants can be produced according to users' requirements. Flame-retardant sealing products are ideal materials for fireproof expansion sealing strips in building fireproof components. It is mainly used for fireproof sealing of various steel fireproof doors, such as the transverse and middle seam sealing of double-layer doors. It can be widely used in fireproof glass lines, waterproofing, fireproofing, sealing and safes for elevator mezzanine doors and other fields.

Fireproof expansion sealing strips have excellent sealing functions, and sufficient materials can be selected to bring out their performance. With the development and progress of The Times, the technology of fireproof expansion sealing strip manufacturers is getting higher and higher at present, and thus the products are also increasing. So, what are the specific classifications of fireproof expansion sealing strips? Let's take a look together!

It is mainly classified by part and use as follows: 1. Windscreen; 2. Door sealing strip 3. Decorative strips, insert strips; 4. Other sealing strips (such as engine hood sealing strips, trunk lid sealing strips, emergency door sealing strips, fuel tank sealing strips, etc.).

According to the materials used, they are mainly classified as: The sealing materials of fireproof expansion sealing strips on automobiles include three types: solid rubber, sponge rubber and hard rubber. The hardness of hard rubber reaches Shore A95. EPDM is combined with steel strips, steel strips, velvet, flocking, PU coating, silicone coating, etc., to ensure the waterproofing, dustproofing, sound insulation, heat insulation, vibration reduction, anti-wear and decorative effects of the car interior and exterior as well as itself. The rubber material for sealing strips mostly uses ethylene propylene diene monomer (EPDM) rubber, which is resistant to aging, low temperatures, water, and chemicals, especially ozone aging. Generally speaking, EPDM sealing strips can be stably used for more than 10 years. Chloroprene rubber with excellent ozone resistance and aging resistance can also be chosen. Considering the technical performance of common compound rubber, sometimes it is necessary to use natural rubber and three types of rubber, namely CR and styrene-butadiene rubber, simultaneously, or to use polyethylene, EPDM and NR rubber at the same time to improve ozone resistance. With the development and maturity of thermoplastic elastomer technology, its application fields are constantly expanding. The new type of EPDM with excellent physical properties and good processing performance can control the long-chain branching in the molecule, improve the vulcanization performance, increase the extrusion speed and product output. Among the raw materials used in the production of sealing strips, the main raw material used in the past, ethylene propylene diene monomer (EPDM) rubber, is also constantly being updated and developed. The application of new thermoplastic elastomers such as TPO and TPV in fireproof expansion sealing strips is also increasing. These materials possess the excellent engineering properties of elastomers and the superior characteristics of plastics. They are easy to process and recyclable. These materials are gradually replacing EPDM products. Only increasingly mature technologies and more effective products can prevent being buried by the market. As the application scope expands and the number of users increases, it can well protect your life when a fire spreads and is a safe product. So, why not choose and use good products?